MYKITA sets standards for sustainable urban production in the fashion industry with its modern manufactory. The Berlin brand has been designing & producing beautiful eyewear under one roof since 2003, today at MYKITA HAUS. The purposeful products combine craftmanship and high technology. Innovation and sustainability are the key of the MYKITA DNA. MYKITA pioneers the industry with its holistic approach. Founder Moritz Krüger was driven by a clear aesthetic vision and the willingness to produce something himself, to be curious and to constantly question the status quo. By the novelty of the first product design, the founder were forced to set up their own production and to develop the machines and processes for the specific needs.

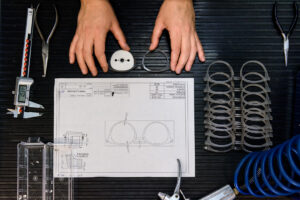

MYKITA has introduced the term “modern manufactory” to describe the multidisciplinary approach of combining art and high-tech processes. In addition to the departments at MYKITA HAUS that accompany the product from conception to final quality control, the modern manufactory involves external experts to form a self-contained manufacturing network.

The frames are handcrafted at MYKITA HAUS in Berlin, with some parts produced in the company’s own manufacturing facility within the EU. Integrity and loyalty are core values at MYKITA and the suppliers of components and technology are long-standing, trusted partners.

MYKITA takes an interdisciplinary approach to driving innovation and developing technology for sustainable options: MYKITA MYLON, for example, is a mass-produced eyewear collection that uses 3D printing technology for low-waste manufacturing.

From the function, fit and look of the eyewear to the variety of styles available in the collections, everything has been developed so that everyone can find their ultimate eyewear – a functional design object for everyday wear that has high personal value and appeal due to superior comfort and fit, as well as distinctive, timeless aesthetics.

Intelligent, purposeful design is the heart of the sustainable products. Every aspect of the eyewear frames and collections has been crafted with the aim of creating long-lasting companions – personal objects to be used and treasured every day.

Efficient use of resources and care for the environment are a part of the brandsl’s holistic manufacturing philosophy. The brand works with selected retailers and offers free repairs, adjustments and professional eyewear cleaning to ensure a long product life.

MYKITA is based on a Made To Order (MTO) business model; only what can be sold is produced, reducing energy and material waste. Independent, owner-managed production – a real rarity in the eyewear industry – together with a fully integrated delivery network is designed to minimise transport and logistics, i.e. the carbon footprint.

Today, in-house production enables independence in terms of production and ownership as well as transparency, important success factors in the fashion industry. The modern manufactory is the primary source of inspiration for expertise, so that ideas can be tested and implemented directly, as expertise is immediately available.

We hope that other designers are inspired by the MYKITA way and that local customers are able to support these great products.

mykita.com

photo by MYKITA campaign SS 2021/ modern manufactory